Steel Builder High-Tech Steel Joint Stock Company (HTSB)

Embracing a greener future for steel

Embracing a greener future for steel

Embracing a greener future for steel

Embracing a greener future for steel

Our Approach

Steelmaking with a conscience is integral to how we do business

With profound respect for our planet, steel production is not merely about producing steel products for high-quality engineering projects.

We envision a sustainable future for the steel industry, eliminating waste and offering green technology solutions, utilizing environmentally friendly materials akin to LEED-certified buildings, actively contributing to the circular economy.

We not only emphasize providing excellent products and services but also dedicate ourselves to building long-term and trustworthy partnerships.

Our mission extends beyond business development to positively contribute to the sustainable development of our community and nation.

We pledge to actively support the investment projects of Ba Ria Vung Tau Province and contribute to the overall prosperity of the region.

Our Services

We provide consultancy in design, manufacturing, and installation of pre-engineered steel houses, high-tech structural steel, diverse commercial projects, as well as construction contracting services.

We build your success

100,000+

600+

3

190

800+

9

BW INDUSTRIAL

Quantity

2600 Tons

BW Industrial

Year Completed

2020

Project Type

WarehouseProjects

HOA PHAT DUNG QUAT 2

The steel complex project, with an investment of 85,000 billion dong, has a capacity of 5.6 million tons of steel per year.

Location

Quang Ngai Province

Quantity

7000 Tons

Investor

Hoa Phat Group

Area

16,000 sqm

Year Completed

2023

Project Type

IndustryVINFAST CAR FACTORY

This is the first car factory in Vietnam to have a complete, integrated and highly automated production process, making it the most modern in Southeast Asia.

Location

Hai Phong Province

Quantity

6,500 Tons

Investor

Vingroup

Area

23,000 sqm

Year Completed

2020

Project Type

IndustrySORA GARDENS SC

The first shopping center in Binh Duong New City

Location

Binh Duong New City

Quantity

2,000 Tons

Investor

Becamex Tokyu

Area

15,000 sqm

Year Completed

2023

Project Type

CivilBW INDUSTRIAL

Location

Binh Duong Province

Quantity

2600 Tons

BW Industrial

Year Completed

2020

Project Type

WarehouseProjects

HOA PHAT DUNG QUAT 2

The steel complex project, with an investment of 85,000 billion dong, has a capacity of 5.6 million tons of steel per year.

Location

Quang Ngai Province

Quantity

7000 Tons

Investor

Hoa Phat Group

Area

16,000 sqm

Year Completed

2023

Project Type

IndustryVINFAST CAR FACTORY

This is the first car factory in Vietnam to have a complete, integrated and highly automated production process, making it the most modern in Southeast Asia.

Location

Hai Phong Province

Quantity

6,500 Tons

Investor

Vingroup

Area

23,000 sqm

Year Completed

2020

Project Type

IndustrySORA GARDENS SC

The first shopping center in Binh Duong New City

Location

Binh Duong New City

Quantity

2,000 Tons

Investor

Becamex Tokyu

Area

15,000 sqm

Year Completed

2023

Project Type

CivilNews and Articles

View moreThe HTSB project at Chau Duc Industrial Park, Ba Ria Vung Tau Province is the third factory of Steel Builder Joint Stock Company

Ba Ria – Vung Tau Province awards Investment Certificate for the High-Tech Steel Structure Manufacturing Plant project by Steel Builder Joint Stock Company (HTSB) in Chau Duc Industrial Park.

The HTSB project at Chau Duc Industrial Park, Ba Ria Vung Tau Province is the third factory of Steel Builder Joint Stock Company

Ba Ria – Vung Tau Province awards Investment Certificate for the High-Tech Steel Structure Manufacturing Plant project by Steel Builder Joint Stock Company (HTSB) in Chau Duc Industrial Park.

Contact us

-

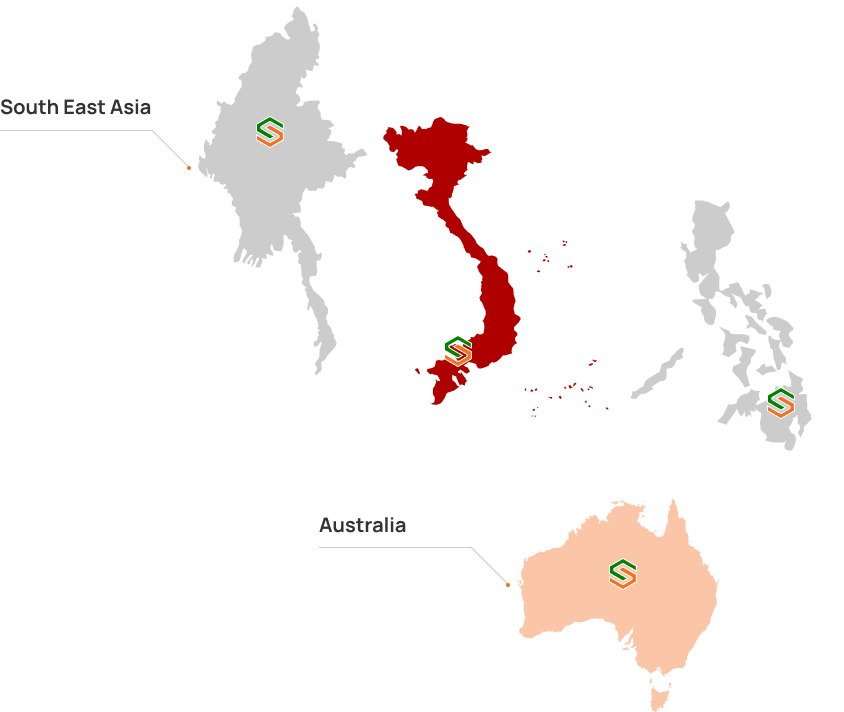

Vietnam Office

- (+84) 28 3990 1888

- (+84) 28 3990 3345

- sales@steelbuilder.vn

-

Australia Office

- (+61) 452 161 783

- Mr. Arthur Visedo

- Arthur@steelbuilder.com.au

-

REPRESENTATIVE OFFICE

65 Pham Ngoc Thach Street, Vo Thi Sau Ward, District 3, Ho Chi Minh City.

Phone: (+84) 28.3990.1888

-

FACTORY

Factory 1: N7 Street, Phu My 2 Industrial Park, Phu My Ward, Phu My City, Ba Ria – Vung Tau Province.

Factory 2: DH423, Group 3, Ba Tri Hamlet, Tan Hiep Ward, Tan Uyen City, Binh Duong Province.

Factory 3: Lot L, Street D.02, Chau Duc Industrial Park, Suoi Nghe Commune, Chau Duc District, Ba Ria – Vung Tau Province.

AUSTRALIA OFFICE

Brisbane Office: 316 Adelaide Street, Brisbane City QLD 4000, Australia

Melbourne Office: 8th Floor, 356 Collins Street, Melbourne VIC 3000, Australia

Phone: (+61) 452 161 783

Mr. Arthur Visedo

Email: Arthur@steelbuilder.com.au

PHILIPPINE OFFICE

Penthouse A1 Alabang Commercial Tower 1216 Acacia Ave., Madrigal Alabang Commercial Area, Muntinlupa City

Phone:

(+63) 9159 638 982

(+63) 9189 212 577

REPRESENTATIVE OFFICE

65 Pham Ngoc Thach, Vo Thi Sau Ward, District 3, Ho Chi Minh City.

Phone: (+84) 28.3990.1888

FACTORY 1

Road N7, Phu My 2 Industrial Park, Phu My Ward, Phu My City, Ba Ria – Vung Tau Province.

Phone: (+84) 25.4389.0998

FACTORY 2

DH423, Group 3, Ba Tri Hamlet, Tan Hiep Ward, Tan Uyen City, Binh Duong Province.

Phone: (+84) 25.4389.0998

FACTORY 3

Lot L, Road D.02, Chau Duc Industrial Park, Suoi Nghe Commune, Chau Duc District, Ba Ria – Vung Tau.

MYANMAR OFFICE

No. 62, 6th Floor (B) Shangone Street, Manigone Sanchaung Town

Phone:

(+95) 9664 289 091

(+95) 9403 413 102